|

This material was published in print form as two separate articles, in the Journal de l'Association des techniciens en prévention incendie du Québec, Vol.8, No.2, June 1997. Hugh Chicoine Certified Fire and Explosion Investigator, p.13-19. Gaston Brosseau Engineer, p.20-23.

In Memoriam: Raymond Michaud 1941-1993, Raynald Dion 1954-1993, René Desharnais 1957-1993, Martin Desrosiers 1962-1993.

Date of the incident: July 27, 1993. CSST report: January 1995. Coroner's report: December 1996. The coroner's report conjures the arson issue, which remains unsolved although a verdict has been rendered for another count. The relief valve of the tank operated normally and the tank did not fail under excessive pressure. The experts who examined the tank shell and the welds in the framework of the public inquiries did not identify any particular "weakness". A fire fighter directed a stream toward the tank and, according to a witness / observer, the explosion occurred in the following seconds.

The fire incident in the following analysis constitutes a rare event. The first characteristic is that the explosion did not occur following a transportation accident (road, railway, maritime, pipeline). The event concerns fire protection operations, i.e., fire fighters in their fire suppression mission.

We have perused documents publicly available, which were submitted to the investigative analysis formulated in the NFPA 921 (1992, 1995) Guide for Fire and Explosion Investigations: "The use of a systematic approach often will uncover new factual data for analysis, which may require previous conclusions to be re-evaluated." (NFPA 921-1995, p.9)

- Accident Inquiry Report # R704867

CSST [occupational health and safety board], Regional Directorate, January 1995, 43 pages and 20 appendices. The CSST is a para-governmental organisation which is responsible for health and safety in the workplace.

- What makes a propane tank explode?

Gaston Brosseau, engineer, previously with the Ministry of Public Security and a former teacher at the college level fire prevention technology program.

- The Coroner's Inquiry Report

File A.88202, 88203, 88204, 88205, by the Fire Commissioner acting as Coroner, December 6, 1996. 32 pages. The Coroner's Office is a "public safety" government organisation.

Other than consulting the aforementioned documents, we also attended the case presentation by those responsible for the CSST inquiry at the annual ATPIQ Convention [Quebec Association of Fire Prevention Technicians] on September 29, 1995. We agree that the CSST is in a legitimate position to support any proceedings intended to "improve the health and safety of fire fighters " in the execution of their duty.

Each extract is clearly identified to its source. We would have liked to read a Court decision in this affair, but the trial before jury for manslaughter ended with an acquittal. The coroner's report presents the judicial aspect in quite another perspective: "... the arson theory ... was rejected by the court, who acquitted the person suspected of this crime". (Coroner, p.9)

According to the CSST "inspectors" who conducted an investigation, the building was a clear frame and timber structure: "The building is a barn that served as a maternity for calfs. ...A small dairy was attached to the front of it... the building forms a cross. ...The interior walls of the dairy are composed of plywood over 5 cm x 15 cm studs (2 x 6 in.) with sheet metal siding outside. The interior walls of the barn are also composed of plywood over old timber framing, covered with sheet metal siding outside. The roofs are made of boards covered with steel/aluminium." (CSST, p.12) Upon verification, I am confirmed that the walls of the structure were filled with mineral insulating pads.

A stationary tank was installed in October 1992 (Coroner, p.8), approximately eight months before the fire. It contained propane, a hydrocarbon: (formula C3H8; rate of expansion 1: 273; relative density 1.52/air1), and had a total capacity of 1002 US gallons (3785 litres). The propane served as fuel to heat the building in winter and to heat the water of a 60 gallon water tank. At the time of the incident, there were 553,2 US gallons of liquefied gas in the propane tank (55.2%) (CSST, appendix 8). This means that the propane tank was approximately half full.

The installation of a safety valve is mandatory on this type of tank, as determined by standard rules and regulations. The cylinder must comply with Section VIII of the Code of the American Society of Mechanical Engineers (ASME), which establishes the safety factor at a minimum of 4, with the result that for an operating pressure of 250 psi, it is expected that the tank would resist a pressure of up to 1000 psi.

''When the pressure within the cylinder exceeds a specified amount, the relief valve is designed to open and allow the gas pressure to be vented, preventing or postponing the rupture of the cylinder. ...Under extreme heat conditions, such as in a fire, the pressure within the cylinder may increase too fast to be fully vented by the relief valve and the cylinder may explode. This is not always the case. Often, the open relief valve and open or heat-damaged control valve will allow the pressurised gas to be expelled without the cylinder itself bursting.'' (Kennedy, Patrick M. and John, Explosion Investigation and Analysis, Investigations Institute, Chicago, 1990, p.146-147)

An expert witness testified at the coroner's inquest confirming Kennedy's statement:

''Gaston K... an employee of the ICG Propane company... has often observed that during major fires, propane cylinders were exposed to fire heat for long periods of time without exploding.'' (Coroner, p.23)

In any case, the more the internal pressure increases, the greater the venting of the gas: at a certain point, the valve whistles noisily.

One must note that an increase in the internal pressure, maintained constantly in excess of the venting capacity of the relief valve can result in the failure of a propane cylinder. This failure is generally referred to as BLEVE (Boiling Liquid Expanding Vapour Explosion).

This explosion belongs to the physical family of explosions (and not chemical). BLEVE is defined as follows in Kennedy (1990):

''A BLEVE occurs when the temperature of the liquid and vapor within a confined tank or vessel is raised, often by an external fire, to such a point that the increasing internal pressure of the liquefied gas inside can no longer be contained and the vessel explodes. This rupture of the confining vessel releases the pressurised liquid and allows it to vaporise almost instantaneously. If the liquefied gas is a flammable such as propane, the large vapor cloud produced is almost always ignited. Ignition usually occurs either from the original external fire that caused the BLEVE or from some electrical or friction source created by the blast or shrapnel effect of the container rupture.'' (p.17)

For most, these notions are to a correct understanding of the mechanisms involved in both the failure of the cylinder and of the subsequent explosion as it happened in Warwick. However, an expert stated that the safety valve indeed limits the risk in such a situation:

''Yvon Ainsley... makes the following remark: ...b) If the relief valve remained constantly open, it would take 15 minutes for the tank to be completely empty." (Coroner, p.20-21)

To assess this expert statement, it is possible to refer to calculations made by the CSST inspectors:

appendix 8: quantity of propane in the tank = 553,2 US gallons;

appendix 10: calculation of the gas released through the relief valve = 6.4 litres/sec;

553,2 US gallons = 2094 litres

2094/ 6.4 litres/sec = 327 seconds, i.e., 5 minutes 27 sec.

The documents consulted offer little information on the fire at the time of discovery and of the arrival of the firemen on the scene. Nevertheless, one learns that:

- The alarm was received by telephone at 9h02 , on Sunday morning. (CSST report, p.13)

''Witness Mario D...the first person on the scene, accompanied by his son... observes that the fire... was extensive in the barn, on the ground-floor level. The fire had broken out through the first-floor windows. Flames sometimes extended outside and reached the cylinder causing it to whistle loudly.'' (Coroner, p.9-10)

''V...whose residence is 500 meters away... saw flames sporadically escaping from the relief valve at approximately 10-second intervals." (Coroner, p.11)

"Upon leaving town, ...fire fighters report seeing a column of dense, black smoke. They reach the scene in approximately twelve minutes time". (CSST report, p.13)

"The relief valve on the propane tank is intermittently releasing flames 10-meters high". (CSST report, p.13)

"Flames are issuing from a window of the dairy and impinge on the tank". (CSST report, p.13-14)

"A fire fighter... standing by the north corner of the dairy aims a stream in the direction of the propane tank". (CSST report, p.14)

At the time of the explosion, only one of the two streams deployed was directed toward the propane tank, and the relief valve had operated three times since the arrival of the responders.

Concerning the operation of the relief valve, the CSST report summarises the operation of the relief mechanism as follows:

''...[ between 09h14 and 09h16] 2nd opening : opens 30 to 40 seconds and shuts 30 to 40 seconds; 3rd opening : 30 to 40 second, then shuts, then the explosion" (appendix 17, CSST, p.240)

According to available documents, the operations involved took place as follows:

"BL is in charge of water supplies, and for that purpose, he ordered two lines to be stretched upon arrival." (Coroner, p.14)

"JCP, a fireman, was installing the pool and was guiding the tanker truck when the explosion occurred." (Coroner, p.12)

The water to the pre-connected lines was supplied from the fire engine tank. Concerning the duration of the stream application segment of the intervention, there are two versions:

1- According to witness MD: The relief valve operated three times before responders began applying a stream to the cylinder. There was a maximum of 10 seconds between the application of the stream and the explosion. (Coroner, p.10)

2- They applied a stream in the direction of the tank during a period of approximately one minute and a half. (CSST report, p.13)

Despite the dissonance in reported facts (a stream operating during 10 seconds or 90 seconds), two remarks made by witnesses must be retained. As is frequently the case, these observations are those of the person who discovered the fire and of the person who arrived first on the scene:

"On June 27, 1993, Ms. SD, MD's wife, informs the Warwick fire service [ at 09h02] that there is a fire at a neighbouring farm..." (Coroner, p.5-6)

"MD: The witness resides approximately 2 miles away. Seeing the smoke, he first thought that the fire was at his daughter's house. HE IS THE FIRST PERSON at the scene, with his son [the owner/occupants of the farm are not home] and observes that the fire is blazing throughout the barn on the ground-floor level. At this point, the fire is breaking out through the first-floor windows. A flame is also issuing from the propane tank and the relief valve is whistling loudly. The relief valve functioned 3 times before firemen began to apply a stream toward the tank. 10 SECONDS ELAPSED BETWEEN THE APPLICATION OF WATER AND THE EXPLOSION. The witness himself was injured by the blast." (Coroner, p.9-10)

From the available data, it appears that the explosion occurred while the relief valve had terminated another 30 to 40 second operation cycle, and at that point a stream was directed toward the cylinder. Consequently, at the time of the explosion, the container was not in a state of excess pressure with regard to the design requirements.

Moreover, the explosion occurred in the first seconds of the application of a stream.

According to the accounts in two of three enquiries led by public authorities, the relief valve functioned several times and with a certain regularity.

Since the valve operated normally, it may be excluded that a pressure increase in the cylinder caused the explosion (as described in Kennedy, 1990). It is therefore necessary to look elsewhere for an explanation of the failure of the cylinder. The mandatory safety mechanism correctly accomplished its function, even if the coroner expresses doubts on the matter: ''Nevertheless, I wonder what is its real usefulness, in case of fire, if it can not prevent the explosion of the tank in circumstances similar to those that occurred in Warwick.'' (Coroner, p.25)

As stated in Kennedy (1990), a relief valve does not constitute an absolute protection. In the case at hand, this safety mechanism functioned normally, with the result that the EXPLOSION WAS NOT CAUSED BY EXCESSIVE INTERNAL PRESSURE BUILD UP IN THE CYLINDER. "An expertise of the relief valve has demonstrated that the mechanism was still functional even after the explosion, although weakened at the seal joint." (CSST report, appendix 14)

"Experts" have given particular attention to two other possibilities:

a) a deflection (or banana effect), and

b) a weakness in the cylinder shell or in the welds.

Gaston Brosseau, P.E. demonstrates in his study that the failure of the cylinder was caused by the expansion of the heated metal which generated pressure greater than the tensile stress of the metal and the circumferential weld of the tank.

"... An unprotected cylinder, exposed to a radiant source of heat, will be subject to an increase of temperature in its shell, particularly in the zone that is not cooled by propane in the liquid phase.

The metal elongation that will occur will be different in the cooler zone than in the overheated part, building an important tensile strain in the relatively cooler part, inside the cylinder at the interface where the level of the liquid is in contact with the shell.

When the propane temperature reaches about 115deg.F, the safety valve on the stationary reservoir will normally open because the pressure will be above 250 psi. Propane release is endothermic, so the liquid temperature lowers in an appreciable manner when the safety valve blows. This has the effect of reducing the temperature of the metal in contact with the liquid propane, aggravating the danger of cracking upon the cyclic operation of the safety valve for some duration.

There are always weld joints in the shell of a reservoir fabricated from steel plates. These welds concentrate stress, on account of the crystallography of the metal that was modified and the residual welding stresses, especially if there was no subsequent thermal relief. One may expect that the assembly will crack in the welded joint close to the place where the cylinder is exposed to radiant heat...."

Professor Brosseau offers a description of the sequence leading to the failure of the stationary tank [for example, the length at the upper part is 0.5 in. longer than at the bottom (12 ft and 0.5 in, as compared to 12 ft below), creating a deflection called the "banana" effect. This would be sufficient to initiate a failure in the metal located at the liquid/gas interface level. A crack in the weld will propagate instantaneously and, most of the time, the cylinder will separate into two missiles which will shoot in opposite directions. Projectiles will be slightly deviated away from the axis of the tank.

"... The steel thermal expansion is calculated by the following rule:

Expansion = L x [delta t] x [alpha t]

where L is the length of the reservoir in inches (for example 12 ft = 144 ")

[delta t] = temperature increase or difference since the initial condition

[alpha t] = 6,5 * 10-6 in/in/deg.F the thermal expansion coefficient for steel

Let's suppose that the reservoir temperature is 650deg.F in the upper part of the shell and 150deg.F in the lower part; that is a Dt of 500deg.F.

When we calculate the expansion in the upper part as compared to the lower part we find that the elongation is 0,562 in. (for 12 feet). This produces an arc that deforms the reservoir lengthwise and is referred to as "banana effect". The equations are extracted from Fundamental of Machine Design, Shigley J.E., McGraw Hill, 1956, p.79; and Mechanical Engineer's Handbook, Marks L.S., McGraw Hill, 1941, pp.1095 and 1658.

Theoretically, the shell of a pressure vessel will resist a circumferential strain twice the intensity of a longitudinal strain, and the longitudinal joint will usually be the first to fail when the metal is subject to overpressure. Therefore it is the axial welded joint (longitudinal) that will fail first.

If a transient temperature variation occurs, localised stresses will develop at the level where an significant temperature gradient exists. This additional stress is caused by the thermal metal expansion which is generated by an external heat source. This stress may be calculated:

s = [alpha t] x [delta T] x E

* where s = stress in psi

[alpha t]= thermal expansion coefficient for steel

[delta t] = temperature differential

E = Young's modulus for steel 30 x 10 6 psi

Op.cit. Fundamental of Machine Design, p.78; op.cit. Mechanical Engineer's Handbook, p.926.

If the shell of a horizontal cylindrical tank is heated in its upper part (propane in the vapour phase) and cooled in its lower part (where the liquid absorbs heat), and supposing that the temperature is at about 650deg.F above and at 150deg.F below, stress is developed in the metal, at the liquid/vapour interface, in the range of 117 000 psi which greatly exceeds the tensile strength of the base metal, and of the circumferential welded joint of the reservoir that is about 70 000 psi, depending upon the steel and welding rod specifications...."

Brosseau's approach is theoretically valid. It explains the phenomenon under study here from the point of view of forces which are applied to the design resistance of a steel assembly up to the point of failure. Brosseau suggests:

"... Ways of preventing the occurrence of a BLEVE

* 1 Implement structural shield to avoid exposure to radiant heat

A priori, the presence of a firewall to protect the tank will permit a safer environment for the firemen. The easiest means is a cement block wall, mounted on a concrete base.

* 2 Design a less brittle reservoir

If the reservoir was not been subjected to a heat treatment after welding, the base metal on each side of the weld will have layers where the metal crystallisation is modified, with the result that the metal tensile strength is locally weaker and stress concentration points can initiate cracks. If there is no means of protection for the tank against heat exposure after installation, it should be subject to stress relief after manufacturing, as for steam boilers. This will lessen the risk of early failure but it will not eliminate it. This additional manufacturing cost is not justified if the tank is adequately shielded. ..."

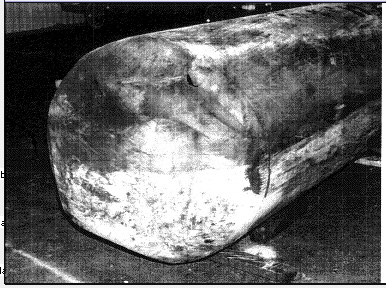

We are grateful to the CSST for providing two photographs which show indications that are helpful in interpreting the case at hand. On examining the outer shell, one notes that the tank has been superficially altered. The demarcation line around the cylinder which separates the liquid and gas phases can be seen in these two photographs by means of two distinct patterns:

photo 1) traces of smoke: black lines are smoke deposits (these occur only on cold surfaces relative to ambient). They do not all disappear in the course of a fire (Gayet, 1973). The reader may observe that the horizontal black lines are not all at the same level. This may be explained: the level of the liquid in the tank decreased each time the valve operated, venting substantial quantities of propane.

photo 1, courtesy CSST

Smoke deposits on the outer shell (mid-level, right side, photo 1) are material evidence that the tank has been massively enveloped in smoke over time, and was therefore in a current of convection that was just as constant. Moreover, on photograph 1, it can be seen that the upper part of the tank displays an altered area. This altered area, which has no definite geometrical shape, indicates overheat on more than half the length of the tank.

photo 2) alteration of the tank surface on the left side is also visible, but there is no trace of smoke (on colour image, provided on request and without delay). This superficial alteration is due to the radiation of the fire.

photo 2, courtesy CSST

Finally, photo2 shows the extremity of the tank which was the most exposed to heat. It displays a hot spot (upper left), apparently oxidised, and is located above the liquid phase of the propane.

As may be seen on the CSST photographs, visible patterns on the tank are such as they were at the moment of the explosion, with the exception of the oxidised sector (the hot spot), which could have been reddish (depicting overheating).

"Expert" reports attached to the CSST report have searched for an explanation in some metallurgic weakness in the tank and welds without, however, reaching any affirmative conclusion. On the basis of these unsuccessful initiatives, we should eliminate all the hypotheses formulated and examined in these "expert" reports.

The most immediate explanation for the failure of the tank would be a thermal shock when a stream was applied, and which actuated or released the forces accumulated in the "banana".

It should be remembered that, in the facts reported by the witnesses, the "BLEVE" occurred some ten seconds after the first pre-connected line was directed at the tank. Ten seconds are sufficient for a stream to dissipate the smoke in order to adjust the range and reach the target (the relief valve ceased to operate and then came the explosion).

The undersigned did not have the opportunity to examine the cylinder, nor the remains of the building. This means that we cannot further analyse the factors involved in either the fire or the explosion.

The circumstances, i.e., the sequence of events remain to be examined in the light of operations undertaken by the fire fighters. This must be done from the point of view of the responders.

In the framework of an investigation, or of an analysis for the same purposes, it is essential to lay out the situation as accurately as possible.

The Warwick fire fighters were not called to the premises of an accident involving a hazmat emergency. They were called to respond to a fire in a farm building and they applied the standardised operations that they systematically undertake in such cases and for which they train regularly.

It is also necessary to note that, in a rural environment, the water available is by no means unlimited. There is no water system. There are no fire hydrants. Deployment is different.

Fire-fighters arrive with the 500-gallon reserve in the fire apparatus. They will dispose of the quantities of water transferred to the portable enclosure that has yet to be delivered to the pumper. Then there will be shuttles from the scene to a supply source. The fire fighters may also draw water from a 30 000 l pool located on the property in order to protect said property.

The entire operation involving men and equipment is carried out in accordance with the tactical possibilities dictated by the layout of the property (access to the site, access to the building involved, according to the continuity of the water supply). The result is that the first two minutes of the response are hardly favourable to observations.

It is in this pragmatic perspective that it is now suitable to review the "facts" presented by the CSST and by the coroner:

- call received Sunday morning, June 27, 1993 at 09:02: mobilisation

- arrival on the scene of witness MD: 09:07 (estimated)

- transportation on the scene, fire engine: 12 minutes; arrival at 09:14

- deployment of 1 or 2 pre-connected lines: 2 minutes.

- explosion at approximately 09:16 - (CSST, appendix 17).

The explosion occurred when the deployment operations were not yet completed. Certain responders were still donning their protective equipment...

The issues formulated in the CSST report and by the coroner were intended to elicit a reflection on the training, knowledge and skills of rural and urban fire fighters:

"... one cannot assign to hazardous duties men and women without providing them with the necessary tools...; the word tool does not refer simply to the equipment made available to them... but also to their theoretical knowledge and field training." (Coroner, p.28)

"... one of the means we have to support them in the performance of their duties is, at the least, to provide them with the necessary tools and training." (CSST, p.32)

The presumption seems to be that the fire fighters should have known what has not even been formulated in two of the three inquiries led by different representatives of the public authorities.

If everyone agrees that an officer provides command of the operations at the scene of a response, authorities should be able to establish the terms of reference according to which the officer should have managed the incident.

These terms cannot be found in the recommendations formulated by both the CSST and the coroner. Neither report refers to the standardised operations carried out by fire fighters in most of their responses (deficient standardised operations are the most frequent basis for lawsuits against municipalities, including water resource management).

The terms of reference have been in existence for over thirty years now. They are contained in an antiquated enunciation that has never been surpassed. However, this enunciation figures nowhere either in the training material or in the information provided to fire fighters:

"In dealing with an exposure problem a commanding officer should not limit his thinking to defensive action only. The most effective defence against extension of an exposure fire may be a strong offensive. A commanding officer should estimate his capabilities of concentrating sufficient volumes of water on the main body of fire to reduce flame production and to absorb excessive heat even though the extinguishment appears impossible. Excessive heat is the heart of an exposure situation. If excessive heat can be controlled, particularly at the points threatening exposed fuel, extinguishment can be accomplished by allowing the fire to consume the involved fuel." (Layman, NFPA International, 1953)

This short extract correctly puts into perspective the essential data that apply to the case at hand. In this perspective 'correctly' means in the perspective of fire fighters called to suppress a fire.

Layman suggests the reduction of the massive production of heat at the source. In the present case, the operation of the relief valve on the tank indicates an immediate danger, although it is counteracted by the mandatory protection mechanism provided.

The attack on a fire from safe positions, if tactically possible, leads to a non-negligible advantage for both the fire fighters and for the municipality. It may be satisfactory to simply inhibit the fire by limiting it to the original building, particularly since farm buildings are easy prey for a fire (a burning barn can seldom be saved).

When examining the diagram produced in the CSST report, it is clear that there were two accesses leading to the burning barn. These accesses provided different strategic possibilities for positioning the fire engine.

According to the principle formulated by Layman in 1953 concerning the risk of exposure, the commanding officer is to:

a) reduce the extent of the fire insofar as this is possible, and

b) consequently, gradually reduce the environment of the tank to a temperature of approximately 212deg. F, that is the temperature of the steam that non-experts often mistake for white smoke, but that fire fighters see as a factor of the efficiency of the operations, a positive step in gaining control of the situation.

If the fire reaches the tank by means of a convection current (the smoke, the flame and the radiation that left on it their respective identifiable indicators, as seen on the CSST photographs), the steam produced by the adequate application of water can travel the same convection current and thereby inhibit the effects of the fire on the tank.

18.1 Based on the following imaginary scenario, reconstruct how the field investigation(s) should have been carried out (insurance investigation, fire investigation, arson investigation, fire safety investigation, industry investigation, health and safety investigation).

Imaginary scenario: Seeing that four fire fighters were killed, the owner/occupant recounts how he set the barn on fire to collect insurance money. However, upon learning that he will be prosecuted not for insurance fraud but for manslaughter, he hires a good criminal lawyer and is acquitted.

18.2 Was this incident a BLEVE as defined in most handbooks? Should that definition be reviewed? Should other past incidents diagnosed as BLEVEs be reassessed?

18.3 What recommendations should have been designed after this incident. Who should have drafted these? On what are these recommendations founded? Who are these recommendations addressed to? What kind of response may be expected?

|